Compact innovation, makes seed extraction a simple process!

About Us

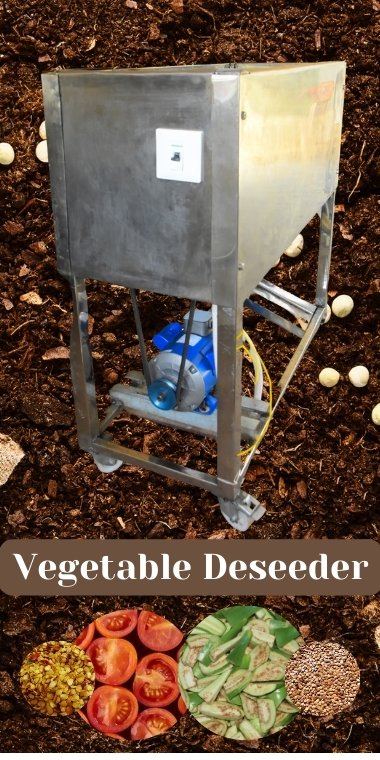

Separating seeds from tomato, brinjal and other vegetables without damaging the seeds

A compact and on-farm vegetable De-seeding Machine invented by a Shiri Dilip Baral is enable to process large quantity of brinjal and Tomato. It is operated by 1 HP electric motor in which high quality seeds get extracted due to continuous threshing action.

He has been engaged in agriculture for the last 32 year.

Extracting seeds from a tomato, brinjal and other vegetable manually can be time-consuming and labor-intensive. Plus, labor costs are very high and finding skill labour is becoming increasingly difficult.

A compact and on-farm vegetable De-seeding Machine invented by a Shiri Dilip Baral is enable to process large quantity of brinjal and Tomato. It is operated by 1 HP electric motor in which high quality seeds get extracted due to continuous threshing action.

Dilip Baral, a progressive farmer, He cultivated various vegetables and cereals in his farm situated in a rural area of Nimapara block of Odisha state. He always tried experimental methods in order to get good productivity. Once in an agriculture fair, he had exhibited a 12 kg cauliflower, which grabbed visitors’ attention. There he was suggested to supply seeds of different vegetables to Odisha Seeds Corporation Ltd.

But, traditionally, seed production has always been a labour-intensive exercise mostly done by unskilled labourers. The ripe vegetables would be harvested, crushed and allowed to ferment in non-metallic containers at room temperature for 10 to 12 hours till the gel surrounding the seeds is degraded by microorganisms. After removal of the pulp, the seed would be cleaned in fresh water and dried. All manually, which entailed engagement of labour hands. Tomatoes, for instance, were crushed with legs and four to five labourers could crush around eight quintal a day. With an average production of 200 quintal from an acre of land, it would take more than a month for seed extraction.

To overcome this, he embarked on developing a machine to automate this laborious task. After various trials & errors, he successfully designed a vegetable seed extractor that could process a large quantity of vegetables in a short time, improving productivity and seed quality. It took him over five years, for the same. He then submitted his innovation details for innovation competition organized by NIF-India. There he received an appreciation award and subsequently received initial support from NIF to develop the innovation further.

Incubated by

NIF Incubation and Entrepreneurship Council (NIFientreC)

Why choose us

Quality seeds for the best germination

The innovative vegetable deseeding machine that not only simplifies deseeding process but also prepares high quality seeds for germination. With vegetable De-seeding machine, farmers can seamlessly transition from harvesting to germination, maximizing the potential of grown vegetables.

Capacity

It can process 1000 kg Tomato and 400 kg Brinjals per hour respectively.

Efficient Deseeding

With its precision deseeding capabilities, vegetable De-seeder ensures that seeds are extracted intact and ready for the next step.

Power consumption

0.8 KWH

Seed Preparation

Once the seeds are extracted, they are gently separated from any remaining pulp, ensuring optimal cleanliness and viability for the germination process.

Labour required

1 person

Germination Support

After deseeding, transfer collected seeds to a suitable germination environment. Extract seed is clean, healthy seeds that are primed for growth.

Mukhyamantri Abinav Krushi Jantrapati Samman

For innovation of vegetable De-seeding device by Odisha Government in the year 2019.